Cold and Damp Heat: The 'Climate Trial' Faced by Cold Storage Equipment

In the daily operation of the cold storage industry, a often overlooked but crucial factor is the direct impact of climate differences on equipment lifespan. The climate difference between severe cold in the north and humid hot in the south is like setting up two completely different "endurance tests" for cold storage equipment. Understanding these effects and taking targeted protective measures directly affects the service life and operating costs of the equipment.

The multidimensional impact of climate differences on cold storage equipment

Challenges in Northern Cold Regions

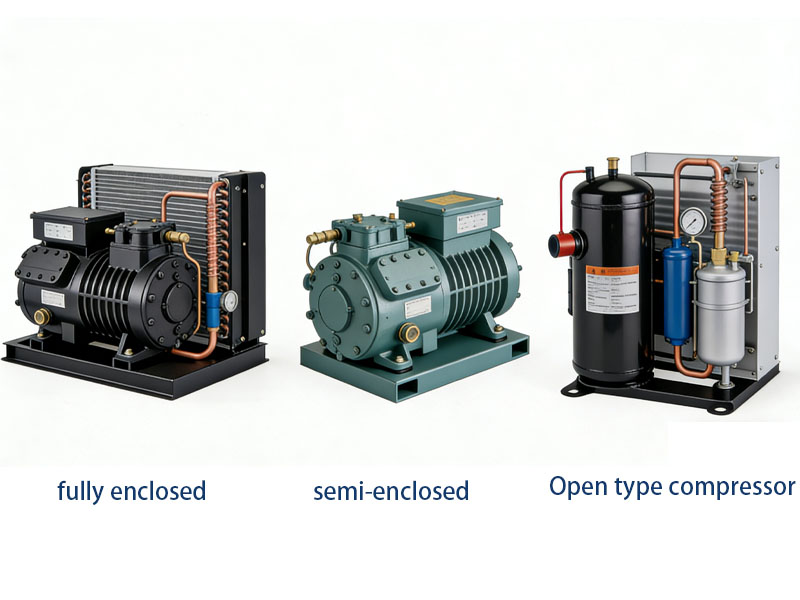

Increased metal fatigue: In extreme low-temperature environments, the brittleness of metal components increases, especially at welding points and structural connections where microcracks are more likely to occurLubrication system failure: The viscosity of conventional lubricating oil increases sharply in environments below -30 ℃, leading to difficulties in starting the compressor and increased wear

Performance degradation of insulation materials: Some insulation materials shrink and deform at sustained low temperatures, damaging the airtightness of the cold storage

The failure rate of the control system is increasing: electronic components react slowly in extremely cold environments, and the LCD display screen may fail

The threat of humid and hot regions in the south

Corrosion Acceleration: In high humidity environments, the corrosion rate of metal components can be increased by 3-5 times, especially in coastal areas where salt spray corrosion occursMold and biological growth: Electrical cabinets and control systems are susceptible to moisture intrusion, leading to short circuits and microbial corrosion

Condensation problem: In high temperature and high humidity environments, a large amount of condensation water is easily generated on the surface of equipment, accelerating the aging of electrical components

Reduced refrigeration efficiency: High ambient temperature leads to an increase in condensation pressure, resulting in a compressor load increase of over 30%

Scientific Assessment: How Climate Differences Quantify their Impact on Equipment Lifespan

According to data from the International Institute of Refrigeration, under the same maintenance conditions:Severe cold regions (annual average temperature<-10 ℃): compressor life expectancy reduced by 15-20%

Damp and hot regions (annual humidity>80%): electrical control system failure rate increases by 25-30%

Coastal salt spray environment: Corrosion rate of metal structures increases by 200-300%

Targeted protection plan

Northern Cold Prevention Plan:

Material selection

Use low-temperature resistant steelSelect low-temperature specialized insulation materials

system renovation

Replace the specialized lubricating oil below -45 ℃Add oil preheating device

Install anti freezing heater on the door frame

Maintenance focus

Conduct low-temperature testing before winterFocus on inspecting welding points and valves

Southern moisture-proof plan:

anti-corrosion treatment

Three layer professional anti-corrosion coatingKey components are made of stainless steel

Moisture resistant design

Install dehumidifier inside the control cabinetUse electrical components with high protection level (IP65 or above)

Strengthen ventilation and drainage around the equipment

Special reminder

Coastal areas require additional anti-corrosion measuresEquipment power should reserve a margin

Practical advice

During procurement:

Clearly inform the supplier of the climate in the region where the equipment is usedChoose a model suitable for the local climate

When in use:

Establish a seasonal maintenance plan (special inspections before winter in the north and before the rainy season in the south)Train employees to identify early faults caused by climate change

Advance reserve of key spare parts

E-mail:Eason@hnshunwei.com

E-mail:Eason@hnshunwei.com Tel:+8615090083672

Tel:+8615090083672